Course: Introduction to Autodesk Fusion 360

🎯 Objective:

Become familiar with Autodesk Fusion 360 as a platform and learn how to create a 3D model.

🔍 What is Autodesk Fusion 360?

Autodesk Fusion 360 is an all-in-one, cloud-based 3D modeling platform that combines:

- CAD (Computer-Aided Design)

- CAM (Computer-Aided Manufacturing)

- CAE (Computer-Aided Engineering)

It is widely used in mechanical design, product design, and rapid prototyping.

🧩 Installation and System Requirements

- Download from: https://www.autodesk.com/products/fusion-360

- Educational licenses are free for students and educators: Link

- Minimum requirements:

- Windows 10/11 or macOS

- 4+ GB RAM (8+ GB recommended)

- Graphics card with DirectX 11 support

- Internet connection (for cloud sync)

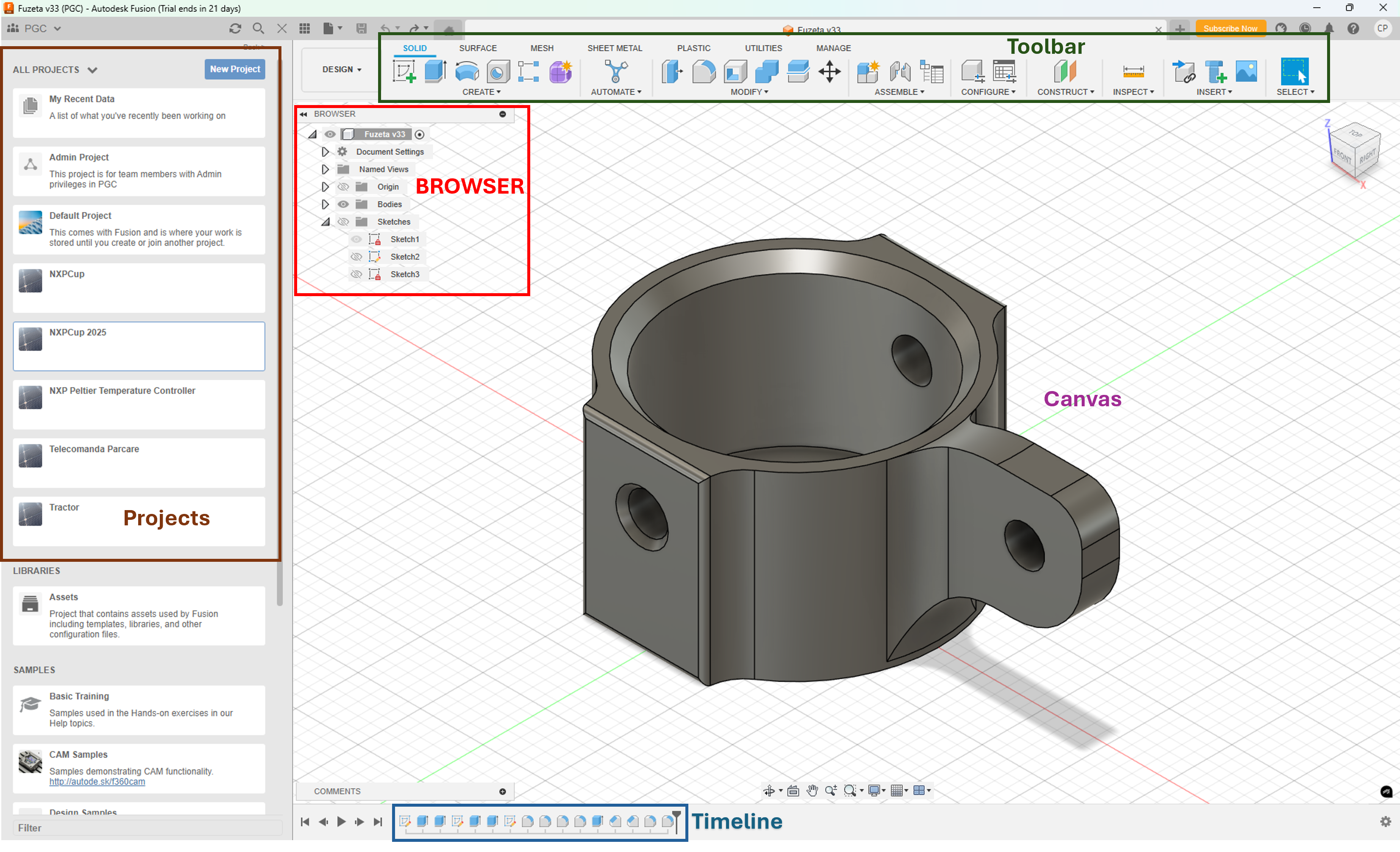

🖥️ Interface Overview

When you open Fusion 360, you’ll see:

- Toolbar: Contains modeling tools depending on the workspace.

- Browser: A tree view of your components and features.

- Canvas: The main modeling window.

- Timeline: History of all modeling operations.

- Projects: Project management panel.

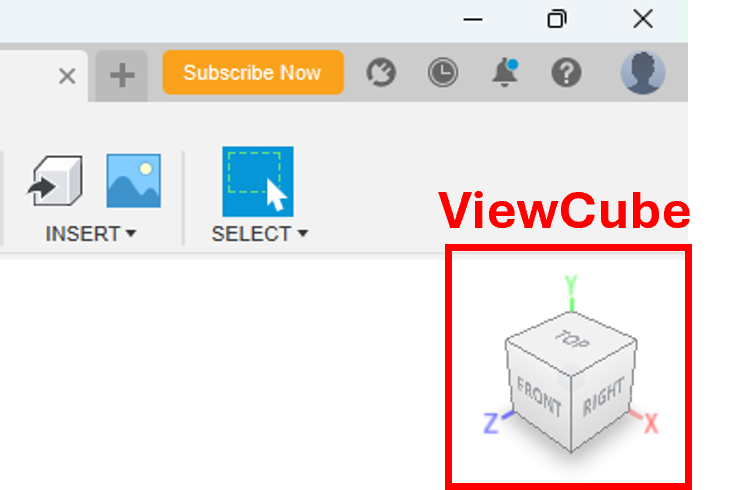

🧭 3D Navigation Basics

You can navigate the 3D space using:

- Orbit: Rotate the view – Hold Shift + Middle Mouse Button

- Pan: Move the view – Hold Middle Mouse Button

- Zoom: Scroll the mouse wheel

Also, use the ViewCube in the top-right corner to switch views.

✏️ Creating a 3D Logo for Your Team in Fusion 360

🧱 Main Steps

- Sketching: The starting point for most 3D modeling tasks. Create a 2D profile on a plane.

- Extruding: Turn the 2D sketch into a 3D solid by pulling it in a specific direction.

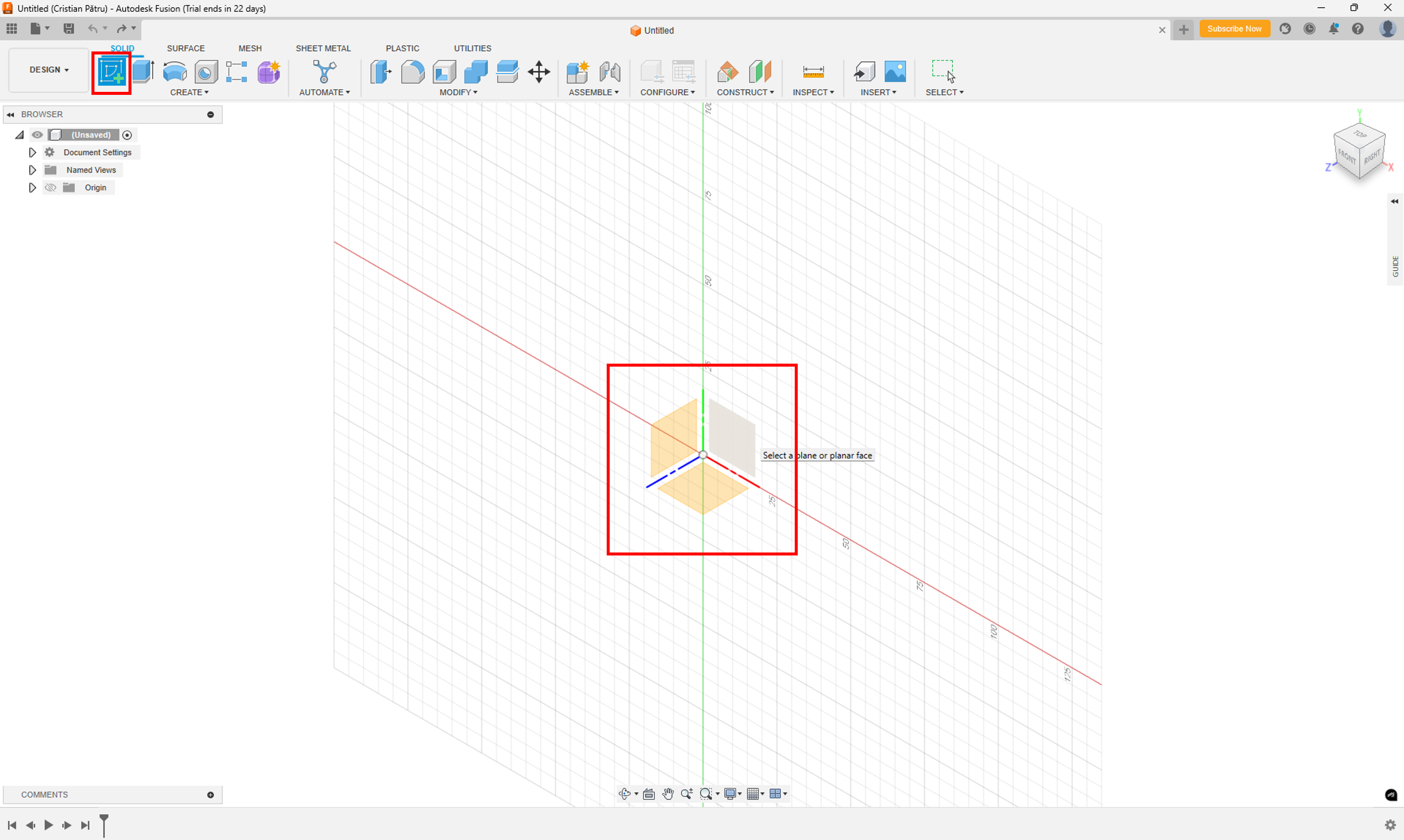

🔹 Step 1: Create a New Design File

- Open Fusion 360.

- Go to File > New Design or press

Ctrl + N. - Save the file (

Ctrl + S) with a meaningful name likeSketch_Extrude_Example.

🔹 Step 2: Create the Logo Body

1. Create a New Sketch

- Click on the “Create Sketch” button in the toolbar.

- Select a plane to draw on:

- XY (top view)

- XZ (front view)

- YZ (side view)

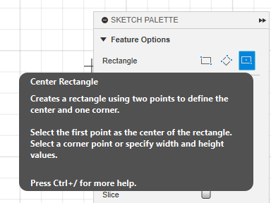

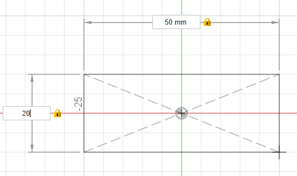

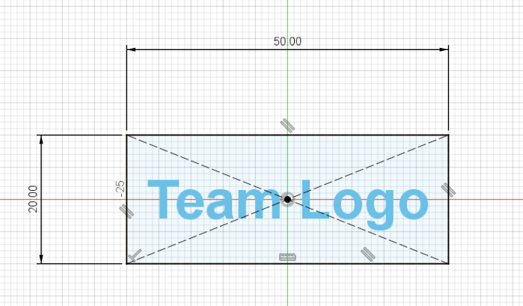

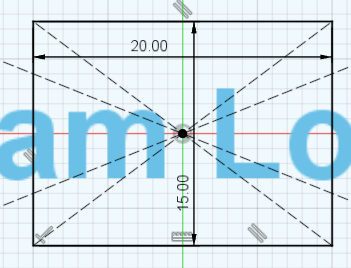

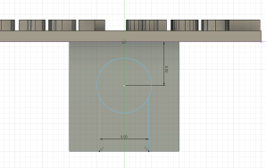

2. Drawing the Base Shape (Rectangle)

Use the sketch tools from the Sketch menu to create the base shape:

- From the Sketch menu, select the Rectangle tool.

- Choose the Center Rectangle option.

- Draw a rectangle with dimensions 50 x 20 mm.

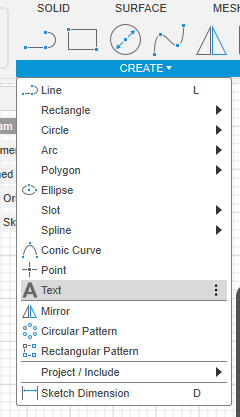

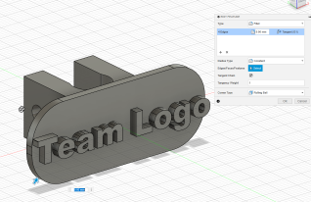

3. Adding the Logo Text

- Select the Text tool from the Create menu.

- Type the desired text and choose your preferred font and style.

- Position the text inside the rectangle.

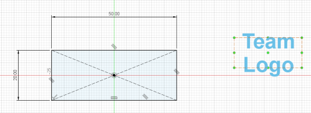

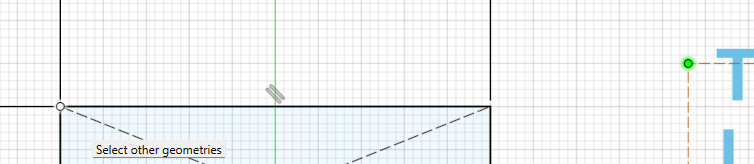

4. Centering and Applying Constraints

To keep the logo in place even if the rectangle is resized:

- Use the Constraints tool to center the logo inside the rectangle.

- Apply corner constraints to align the logo with the rectangle.

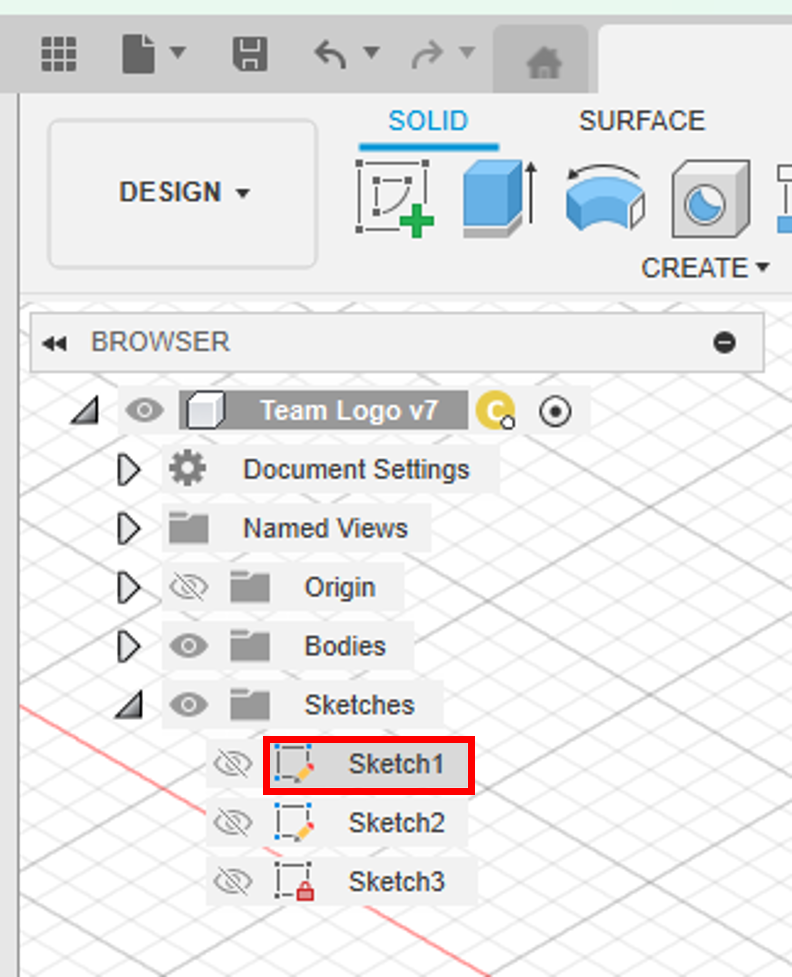

- Final constrained sketch result:

5. Exit Sketch Mode

Once the sketch is complete, exit sketch mode by clicking Finish Sketch.

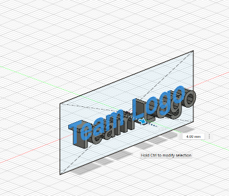

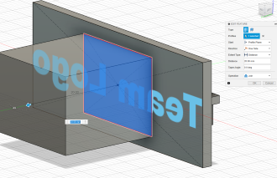

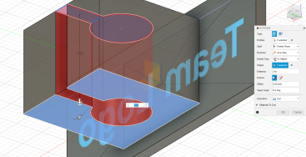

6. Extrude the Text

- Select the Extrude tool from the Create menu.

- Select the text to extrude.

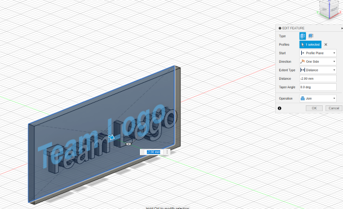

7. Extrude the Base (Rectangle)

- Extrude the rectangle to create a 3D plate for the text.

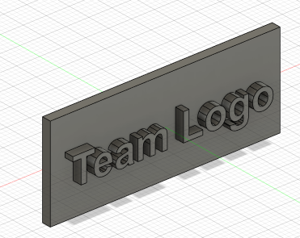

8. Final Logo Body

- This is how the logo body should look.

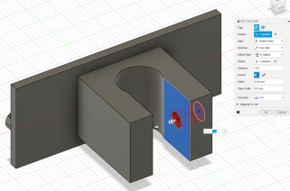

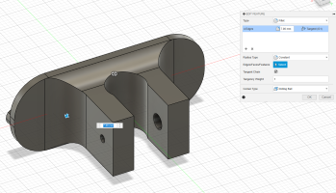

🔹 Step 5: Create the Pipe Clamp

1. Open Sketch1

- Double-click Sketch1 in the Browser.

2. Draw Clamp Rectangle

- Place a rectangle centered within the logo rectangle.

3. Extrude the Clamp Rectangle

- Exit sketch mode.

- Use the Extrude tool and set the depth to 20 mm.

4. Create Sketch for the Pipe Hole

- Create a sketch on the top face of the clamp.

- Draw a circle 8 mm from the logo, centered left-to-right.

- Add two parallel lines from the circle to the rectangle edge (to allow pipe insertion and locking).

5. Extrude the Hole

- Exit the sketch.

- Use Extrude, select the circle and area between the lines.

- Set Extent Type to "To Object" and select the opposite face of the clamp.

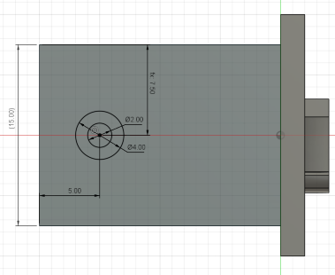

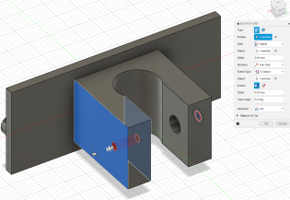

6. Create a Clamp Locker

- Create a sketch on the right side of the clamp.

- Draw two circles (2 mm and 4 mm diameter), 5 mm from the back, vertically centered.

7. Extrude the Clamp Locker

- Use Extrude to create the 4 mm hole. Set Extent Type to "To Object".

- Use Extrude to create the 2 mm hole. Set Start to "Object" (the inside face), and Extent Type to "To Object".

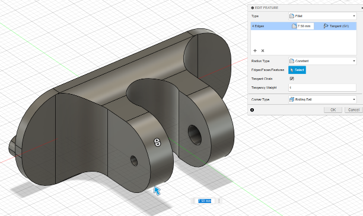

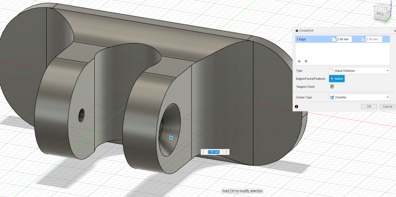

8. Use Fillet to Smooth Edges

- Select the Fillet tool from the Create menu.

- Choose the edges to smooth and set the radius to 9 mm (or any value).

- Repeat for other edges as desired:

9. Create Chamfer for the Locker Screw

- Select Chamfer from the Create menu.

- Select the hole edge and set the chamfer value to 2 mm.

🔹 Final: Logo Body Finished